How to cast your own bullets

This article will show you step-by-step how to cast your own lead bullets using Lee Precision Bullet molds for use in reloading my 45 ACP ammunition. Please note that I am no expert in this process but I have been making my own lead bullets for years.

From the very first time I learned how to do it, I have been following the directions from the Lee reloading guide and have had great success in reloading my own ammunition including casting my own lead bullets.

If you are just beginning reloading, See: How to Start Reloading Ammo

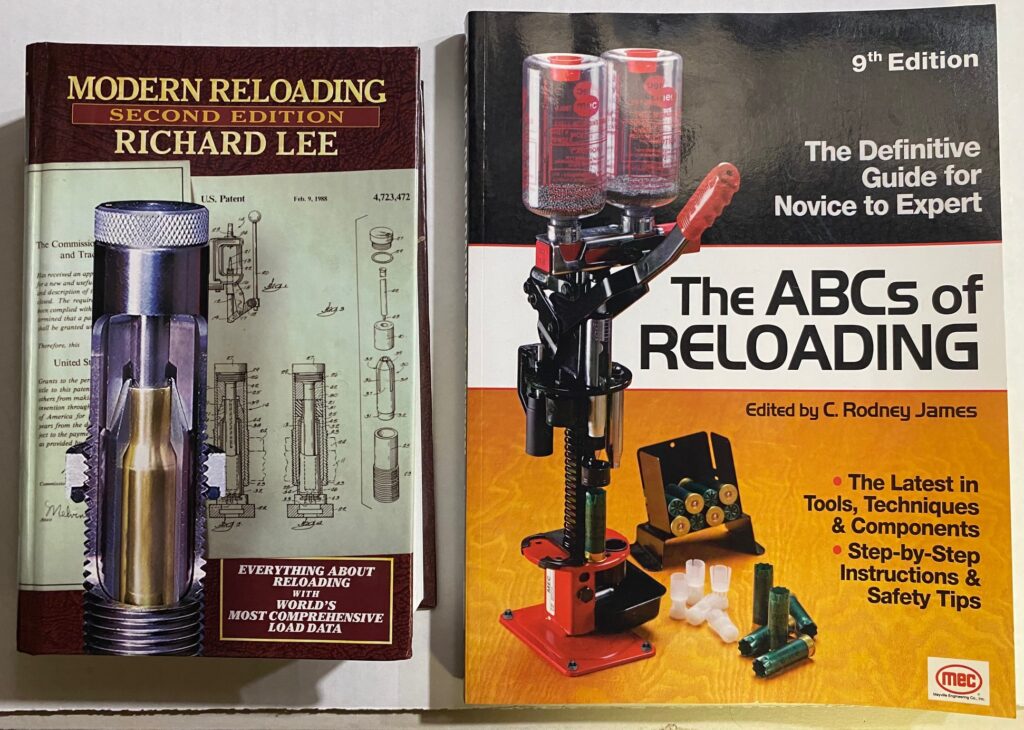

Here are the books that I used to learn how to reload and cast my own bullets:

2021 Modern Reloading Manual 2nd Edition – New Format – LEE PRECISION

The ABC’s of Reloading: The Definitive Guide For Novice to Expert

**Always wear gloves and eye protection when working with molten metals. Also, be sure you have adequate ventilation because breathing in lead fumes is hazardous to your health! I cast my lead bullets right outside my garage.

Why make your own bullets?

There are a couple of reasons why someone would want to make their own lead bullets. I cast my bullets because I enjoy the process and the satisfaction of making my own ammunition as well as helping to keep the cost down.

Most ammunition you buy at the gun store use copper jacketed lead bullets. The bullets we will make using this process are all lead, without a copper jacket. If you reload your own ammo, you can choose what type of bullets you use. Lead (without a jacket) is usually a lot cheaper due to the fact that it is easier to produce. And if you make them yourself, it is even cheaper!

Although it is considerably less expensive per bullet to make your own, you must also take into consideration the amount of time and the initial outlay of a bit of money to acquire all the tools you will need. I began casting my own bullets many years ago and I still enjoy it to this day. I find an afternoon of casting bullets in my garage on a nice day to be relaxing and enjoyable.

Lee Precision vs other Reloading Manufacturers

There are several manufacturers of reloading and bullet casting equipment. My experience has been with Lee Precision reloading equipment and methods. I am not familiar with other products, other than the fact that Lee makes high quality, functional equipment that is the least expensive in the industry. I have been quite satisfied with the quality and durability of their tools and have been using them to successfully reload for about 5 years now.

How To Cast Your Own Lead Bullets Video

What are some of the pros and cons to making your own lead bullets?

Pros:

- Less expensive ammo.

- Satisfaction of creating your own ammunition.

- Learn about ammunition.

- Relaxing way to spend an afternoon on a nice day (or even a rainy day!).

Cons:

- Some firearm manufacturers will void your warranty if you use bullets that are not copper plated mostly due to the fact that lead bullets tend to leave more residue in the barrel.

- When using lead bullets, you will want to clean the bore of your firearm more often and use a good bore brush to make sure you clean out all the residue.

- As mentioned earlier, casting your own lead bullets is time-consuming.

Basics of casting bullets

I am not an expert in lead bullet casting. However, I have been doing this for many years and have never had any issues. I am sure there are many different ways to do this, but I am going to show you the way I do it and it is relatively straightforward.

- Casting

- Sizing

- Lubricating

The process for casting your own lead bullets is relatively simple. Basically you’re going to take a Lee bullet mold and fill it with molten lead, let it cool for a few seconds and then drop it into a bucket of cold water. After making as many bullets as you need, you will then “size” them. This means forcing each one through a sizing die to ensure they are all exactly .452 (or whatever size bullet you are making) in diameter.

Lastly, you will lube them. Lee makes a great, inexpensive lube called “Alox”. You will simply place the bullets in a container, drizzle some alox on them and them tumble them around in the container to coat them. Then you let them dry overnight on some wax paper and they are ready to load.

Melting the Lead alloy

Lee precision makes a lead melting device called a production pot that holds up to 10 or 20 pounds of lead depending on the model.

The production pot holds the lead about 6 inches above the work surface and has a spout at the bottom and when you open the valve the spout allows molten lead to pour out into your mold. When I set myself up to cast some lead bullets, I will generally make three or 400 bullets in a couple of hours.

Making your own lead bullets is really not difficult at all once you learn the process. You don’t really need a lot of tools and supplies, and here is a list of what you will need. In this article I will be loading 45 ACP bullets, but the process is exactly the same for any caliber of hand gun bullet.

Tools and supplies for lead bullet Casting

Always use gloves and eye protection when working with hot lead!!

- Lee Production pot

- Lee bullet mold

- Lead

- Linotype alloy

- Lee Alox Beeswax Mix

- Bucket of cold water

- Wooden stick

- Cookie sheet

- A couple old metal spoons

Lee Production Pot

Lee makes a couple versions of this item. I have the 10 lb version which can hold 10 pounds of lead. There is also a 20 pound model if the 10 is hard to find. You can find these on here on Amazon.

Lee Bullet Mold

Lee makes a lot of different molds for casting bullets. The one I use is a double cavity (makes 2 bullets) .452 diameter 228 grain weight. Lee Model 452-228-1R. You can find LEE bullet molds at the following links:

Lead

This is usually made up of old wheel weights or even reclaimed bullets and melted down into ingots or bars of lead weighing 1-3 lbs each. I get mine from various sellers on eBay but there are also companies that sell it online, such as:

Amazon also carries Lead from rotometals.com

You do not want PURE lead as this is too soft, so you want lead that has some tin in it. Tin will make the bullets harder.

If you want to test the hardness, you can purchase the Lee Precision Lead Hardness Test Kit. I do not have this kit, I just make sure I add some Linotype alloy to my lead and I have not had any issues. Linotype alloy is composed of lead with approximately 4% tin and 12% antimony. Antimony also increases the hardness.

If you want to be sure of what you are getting, buy from www.brownells.com, they have all the hardness properties listed just for making bullets. You can also try www.rotometals.com

Linotype Alloy

I buy this as well as lead to mix in my melting pot. This helps assure that I have ample hardness since I do not always know exactly what I get from the sellers on eBay. Linotype is a lead alloy that is about 4% tin and 12% antimony.

If you buy bullet casting lead that already has tin and antimony in it, you do not need to buy Linotype alloy.

Lee Precision Alox Beeswax Mix

This is used to lubricate the bullet mold and acts as a “flux” to be added to the molten lead. This can be found here.

Other Useful Tools

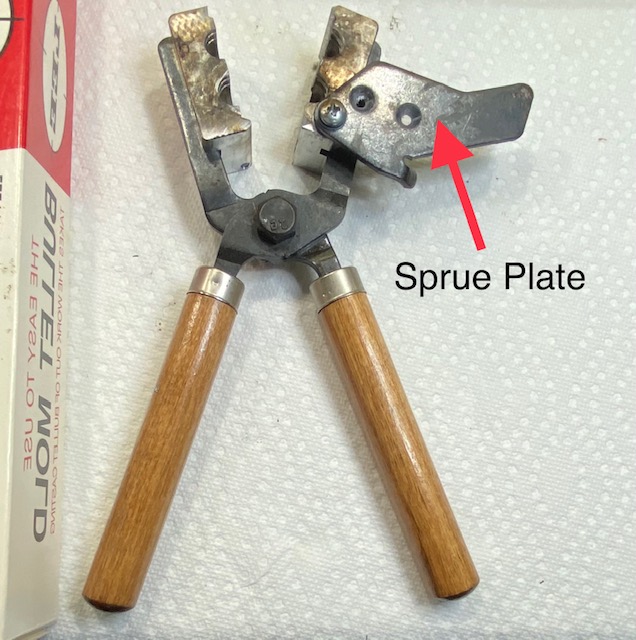

The other items complete my set-up. A bucket of water to catch and cool the bullets when I drop them out of the mold. I use a wooden stick (broom handle) wrapped in duct tape to help open and close the sprue plate on the bullet mold without severely burning my hand. I use a cookie sheet just to catch all the hot lead that will fall onto it during the process and protect the table or bench I am using. The spoons are to scoop up the excess lead pieces and put them back into the melter.

Bullet Casting Steps: Casting

First we will actually be molding the bullets.

You will want to turn on your Lee production pot 20 to 30 minutes before you want to start to let it heat up to 600 or 700° degrees F and put your lead in there and allow it to melt into a liquid.

2. Smoke the bullet cavities. Using a match or a butane lighter. Hold the flame under the mold and allow the smoke to coat the cavities with some sort which will help to season the mold and prevent the bullets from sticking. You may need to do this each time you cast bullets but after a while it may not be necessary.

4. Lubricate the bullet mold. Use Lee alox beeswax mix or similar high temperature lubricant. Do not use the liquid alox which is designed to go on the bullets when they are cold as this will bake on and cause problems. Put a tiny bit of beeswax on the alignment pins and the sprue pivot screw this will lubricate the essential areas. You can just touch the stick of beeswax to the lubrication points and the heat will draw in the lube.

You will close the bullet mold and close the Sprue Plate on top all the way in order to create the mold cavity to pour the molten lead into.

If there is a gap between the halves when you close the mold, tap the closed mold several times with the wooden stick and it should close up all the way.

If you see a gap like this:

Use the wooden stick to tap the mold a few times and it should close up nice and tight:

5. Fill the cavities with molten lead. Hold the bullet mold 1/4-1/2 inch under the production pot and open the valve and allow the molten lead to fill the mold through each hole in the sprue plate. Allow a puddle to formulate on top of the sprue plate that connect the holes.

6. Open the Sprue plate. As soon as the puddle on the sprue plate solidifies (only a few seconds), immediately strike the sprue plate with your wooden stick to open the sprue plate. This will slice off the excess lead and leave a nice flat surface on the bottom of the bullets.

7. Remove the bullets from the mold. Open the mold and allow the bullets to drop out into the bucket of water. You will likely need to strike the mold a few times to shake them loose.

8. Repeat steps 5 through 7. Do this until the mold gets so hot that the lead takes a long time to solidify. At this point you can take a break and let is cool down, or you can touch the mold to a wet sponge to cool it down quicker. Be careful! Any molten lead that cools quickly can explode and splatter hot lead everywhere!

Bullet Casting Steps: Sizing

This step may be skipped if your bullets are properly sized right out of your mold. I personally size all my bullets just to avoid any issues. Sizing simply means to make them all the same exact diameter.

This is accomplished by pushing each bullet through a sizing die on a press. This will squeeze any oversize bullets down to the .452 (this will be different depending on the bullet you are casting) I use a Lee Precision Breech Lock Reloader Press.

Tools needed to size your Lead cast bullets

**Note. Lee Precision recommends lubricating the bullets before sizing. (see next section for lubrication) I recommend you do it their way. I used to do it that way but I have done the sizing first with no issues for years. I found that the lube gunks up my sizing die.

Also, it makes more sense to me to lube AFTER sizing so there is lube on the widest part of the bullet where it is most needed.

- Single stage press or turret Press

- Sizing Die for the bullet caliber you are casting

The sizing process is simple, you just need to take one bullet at a time and run it through the die into the container. Some will be easy to push through and some will be harder, but when you are done, all your bullets will be the same diameter and will fit properly into the brass and then into the chamber of your gun.

How to Size Lead bullets video

Here is a short video on sizing lead bullets using Lee Precision sizing die, reloading press and reloading stand.

Bullet Casting Steps: Lubing

This also is a simple and quick process. Lubricating the bullets is a very important step in the bullet-making process. Properly lubed bullets will cause much less “leading” in your barrel as you shoot. It prevents small amounts of lead from building up inside the barrel of your gun, which is not only harder to clean, but can cause accuracy issues.

Supplies to Lubricate your Cast Lead Bullets

You only need a suitable plastic container and some Lee Alox Bullet Lube (or equivalent)

Simply place the bullets in a plastic container, drizzle a small amount of Lee Alox Lube on them, close the lid and slowly tumble them in a circular motion until the bullets are all evenly coated.

Spread out the coated bullets on a sheet of wax paper and allow them to dry overnight.

After they are dry, you can keep them in a container until you are ready to reload your ammunition.

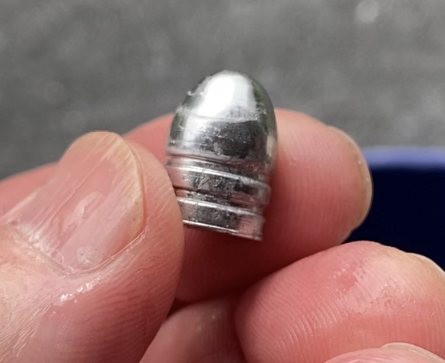

Your final product will look like this:

How to Cast Lead Bullets Final Thoughts

This is the first installment on my upcoming reloading series of articles. I hope this has help you in your search for information on how to make your own lead bullets.

I also have many articles on cleaning and maintaining your firearms. How to Clean a 1911, how to Clean an M&P Shield, etc.

Here are the two excellent books I bought and read on the subject of reloading. I learned everything I know from these books and several years of experience!

The first book steps you through all the equipment, processes and tips you need to reload your own ammunition. This book helped me decide which reloading press to get and what else I would need to be successful and safe with my reloaded ammo.

The second book give you all the data you need to know on each type of cartridge you want to reload including how much powder to use, what kind of powder, what kind of powder to use for different bullet weights, etc. This data is critical for safe reloads!

The ABC’s of Reloading: The Definitive Guide For Novice to Expert

2021 Modern Reloading Manual 2nd Edition – New Format – LEE PRECISION

Thanks for reading this article and please leave comments or questions below and I will respond as quickly as I can.

In the article you mentioned sizing and then lubing bullets. You should lube before you size to avoid leaving lead in the sizing die and to make it easier.

Rob, thanks for the comment. You are correct. I added a note to the article. However, I have sized first for years with no issues. I found that sizing rubs off the lube in the most important areas (grooves) as well as gunking up my sizing die. For a while I was lubing, sizing, then lubing again but decided that was extra work. Thank you for commenting!

Dave

I did 340 GR FN they came out 348. Melted them down and repoured and they came out

348 to 350. Lead was 20 to 1 , temp 740 to 765. what happened?

Personally, I would not worry about it. Mine come out heavy too. You could try adding more antimony if you want but don’t sweat it.

Dave